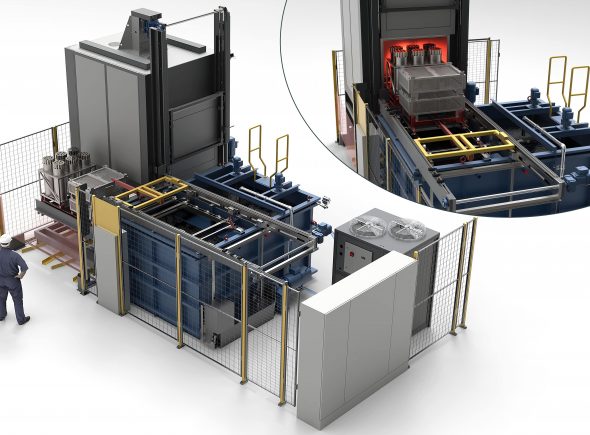

Horizontal transfer heat treatment furnaces for

light alloys, solution treatment and quenching

This multi-purpose furnace enables you to carry out not only solution treatment and quenching but also tempering and annealing of your parts. SAT manufactures heat treatment furnace with horizontal transfer.

Why a heat treatment furnace with horizontal transfer?

The Alu-SAT 1000 heat treatment furnace is the range of horizontal transfer furnaces for solution treatment and quenching of light alloys which are the most versatile and the most economically appropriate for small and medium-sized loads.

By combining two movements (one horizontal on exit from the furnace and one vertical for quenching), horizontal heat treatment furnaces can provide short transfer times of as little as 7 seconds.

Several versions are available:

- Furnace alone, manual, without quenching tank for solution treatment of light alloy parts with small dimensions or a profile requiring hand quenching.

- Furnace with quenching tank and a mechanized system guiding the load out of the furnace and into the tank by manual action

- Fully automated furnace managing the solution treatment, the transfer time, the quenching and the removal of the parts from the bath.

Depending on your requirement, we can offer you control solutions ranging from a simple control system to complete piloting and management of your cycles.

The international environment of our industrial partners has allowed us to fully master today’s standardization systems.

General design standards: CE, UL, AQSIQ, etc., but also the standards linked to specific sectors such as NADCAP, AMS, BAC and CQi9.

Thermal equipment appropriate for the various metallurgical states of aluminium alloys: T4, T5, T6, T7 and T8.

Homogeneity of +/-3°C at 500°C

Load processed per cycle: 600 kg

Quenching solution treatment T4 AMS class 1, transfer time 7 seconds,

Manufacturing of aviation racks.

Quenching solution treatment T4, class 2, transfer time 10 seconds

Manufacturing of sheet metal aircraft parts.

Load 5 tonnes, AMS Class 1, transfer time: 14 seconds

Furnace specially adapted to the aviation forging process and equipped with a multi-purpose loader capable of loading/unloading a whole line of treatment furnaces.

Quenching solution treatment T4, class 2, transfer time: 10 seconds

Manufacturing of sheet metal aircraft parts.

AMS 2750 class 1.