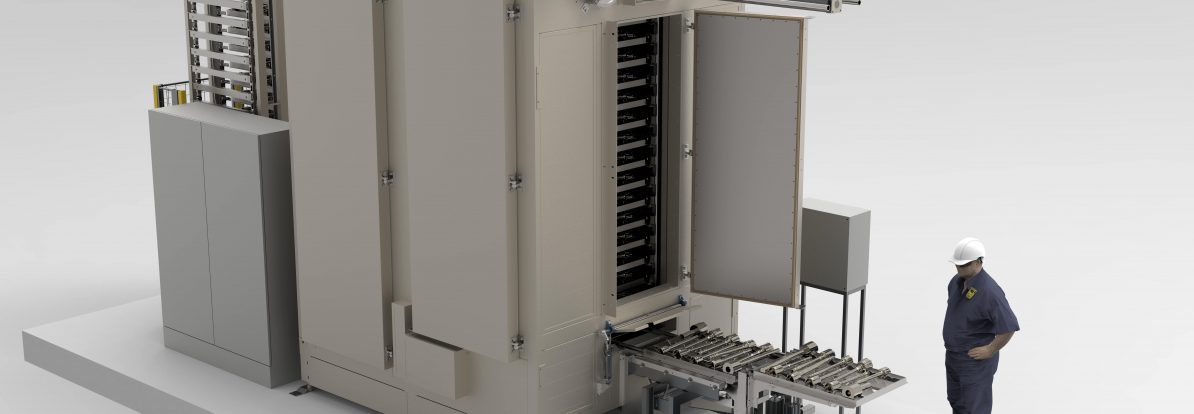

Continuous steel tempering furnace

SAT Thermique has designed and produced for a Tier 1 automotive supplier, a continuous steel tempering furnace, based on the plate lift principle.

SAT Thermique has designed and produced for a tier 1 automotive supplier, a continuous steel tempering furnace, based on the plate lift principle.

The parts, tulips (component of the cardans of your car), are positioned on trays, themselves placed on a turntable by a robot in front of the entrance to the oven.

After a 180° rotation, the plate, containing 10 tulips, is transferred to the oven, and begins its stay at 165°C, to carry out the tempering treatment, essential for the solidity of your transmission.

The trays go up step by step, thanks to chain elevators, before being transferred to the second elevator, to go down again.

A final movement brings the load back to the exit.

This fast and precise furnace can process a part every 22 seconds, i.e. 1200 kg per hour. It operates 24 hours a day.

Alongside this, SAT has designed a storer allowing the installation to be emptied in the event of a stoppage of the downstream production line, allowing perfect integration combining performance and flexibility.

The work of SAT experts is always present in your daily life…

#steel #industry #automotive #industrialfurnace #satthermique