Ovens for curing of composites at temperatures up to 450 °C

SAT offers a range of industrial ovens specifically adapted to all curing processes: pre-impregnated, RTM (resin transfer moulding), infusion, filament winding, honeycomb drying, curing, post-curing, pultrusion, thermoforming, etc.

SAT composite curing ovens are already used not only by the most prestigious aviation equipment suppliers but also in the automotive and sports industries.

SAT offers a genuine complete turnkey heat treatment solution, standard or customized ovens, which takes into account all the parameters of the composite curing process:

- Temperature: precise and controlled thermal cycles (temperature rise, fall and uniformity), and an air flow adapted to the weight and shape of your moulds. Able to exceed 450 °C, our ovens allow the use of all thermosetting and thermoplastic resins.

- Vacuum: from simple draw-off to a complete vacuum unit (pump, tank, filter, measurements, etc.)

- Pressure

- Resin injection (Infusion, RTM)

We also offer a very complete user-friendly supervision system capable of managing all the parameters (temperature cycles, vacuum, pressure, resin injection, encrypted recording complying with AMS, CQI9 and NADCAP, batch management), etc.

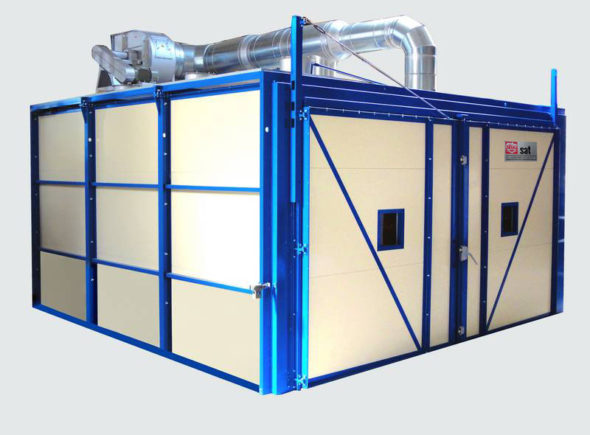

Polymerization of composite materials oven

Complete infusion line incorporating oven, vacuum system, resin injection system and general supervision.

Polymerization of composite materials oven

Complete infusion line incorporating oven, vacuum system, resin injection system and general supervision.

Polymerization of composite materials oven

Composite fan blade curing oven, temperature 180 °C.

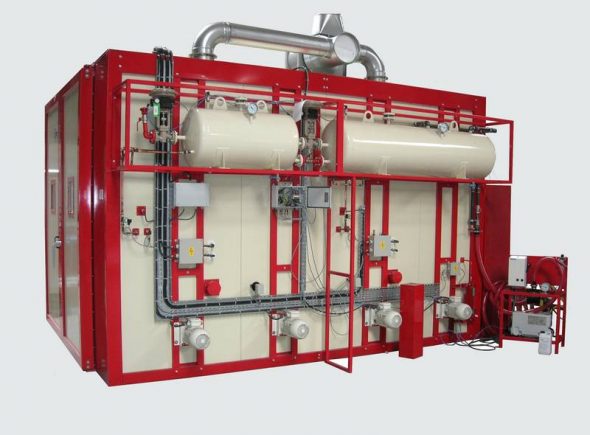

Polymerization of composite materials oven

Oven for infusion process, 250 °C.

Polymerization of composite materials oven

Complete infusion line incorporating oven, vacuum system, resin injection system and general supervision.

Customer Application

Manufacturer of composite curing oven for the automotive industry

Find out more