Industrial furnace and oven manufacturer

The diversity of SAT’s industrial furnaces and ovens and the wide working temperature range, from 20 to 750 °C, enables us to be involved in a very large number of manufacturing processes: coating curing, drum pre-heating, elastomer curing, drying varnish, drying motor winding…

FURNACES AND OVENS FOR curing of coatings

Powder, liquid or high temperature, all these paints can be cured in static or continuous furnaces.

Application of non-stick, anti-corrosion and dry lubricant coatings, application of sprayed metal coatings (metal spraying).

Application of synthetic, epoxy and polyurethane paints.

PTFE (PolyTetraFluoroEthylene), FEP, PFA (PerFluoroAlcoxy), ECTFE/HALAR (Ethylene ChloroTriFluoroEthylene), PEEK.

Drum heating OVENS & TUNNELS

Pre-heating of materials before unloading requires precision and may be subject to restrictive standards such as ATEX.

SAT ovens and tunnels meet these requirements.

Any type of heating can be envisaged: dual energy, electrical, gas, steam, coolant, etc.

Degassing OVENS & FURNACES

An important step in the qualification process for screws and fastening systems. SAT ovens are particularly suitable for this.

Degassing is an operation to dehydrogenate a part which has been weakened by hydrogen. This operation is generally carried out after electrolytic treatment on steels which have undergone heat treatment.

Degassing is carried out in a degassing furnace set to a temperature and a time determined by the class of the steel, its strength, its material and/or the specifications which accompany it.

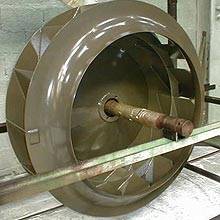

FURNACES AND TUNNELS FOR the elastomer curing process

Post-vulcanization processes for products such as: hoses, seals, silent blocks, shock absorber stops, bellows, sleeves and grommets, etc.

An oven which is 100% airtight thanks to the continuous welding of the interior sheet metal for optimum protection of the insulation, eliminating accumulation of hazardous materials (solvents, etc.) and the fire risk presented by this residue.

Extraction sized according to the type of elastomer used, in order to limit clogging of the installation and maintenance costs.

OVENS & TUNNELS FOR MANUFACTURING OF PARTS IN polyurethane and polycarbonate

- Curing of polyurethanes

- Pre-heating of polycarbonate plates before forming

Varnish drying and curing OVENS

Electric motor windings, very common in industry, are baked in ovens to dry or cure the varnishes.

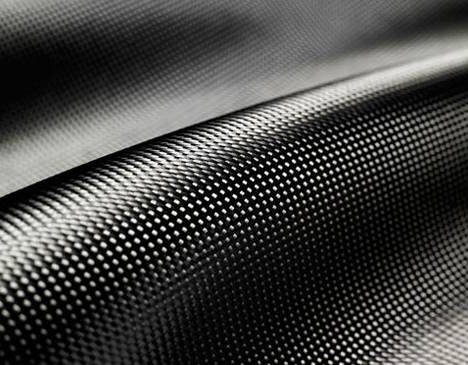

Tunnels for HEAT TREATMENT ON TEXTILE FIBRES: GLASS FIBRE AND CARBON

Fibre sizing tunnel.

“Textile” sizing applied on filaments on exit from the die consists in depositing a binding agent providing inter-filament cohesion, reducing abrasion and facilitating subsequent operations (weaving) and preventing the forming of electrostatic charges.

Oven for sizing on woven textiles to enable subsequent impregnation of resin on the fabric.